I have decided to look at the work of Dutch architect Rene van Zuuk for the assignment. I am particularly interested in his patterned concrete facades like the one in the photos.

I was interested in the lecture we had on concrete panels and of learning of the different ways they can be treated. I have always thought they made such ugly buildings so was very interested to hear and see how they can be used in a more asthetically pleasing way. I like the idea of exploiting the advantages of pre-cast concrete panels but of making them much more interesting and beautiful.

Rene van Zuuk seems to search for ways of using simple and low cost technology and construction techniques to make buildings that stand apart from the norm and have a 'special' quality to them.

In a number of his buildings he uses repeating panels. The panels are relatively simple to construct but when used continually, create a visually striking effect.

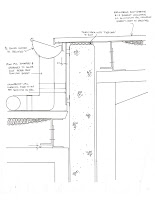

Attaching the braces to the panel.

Attaching the braces to the panel.